DigiCell M24 Progress Meeting held in Linz

The new year is still young and batteries are fully loaded – perfect conditions for holding the bi-annual DigiCell Progress Meeting. This time, the meeting was jointly hosted by Keysight Technologies and Johannes Kepler University on 21-22 January 2026 at their premises in Linz.

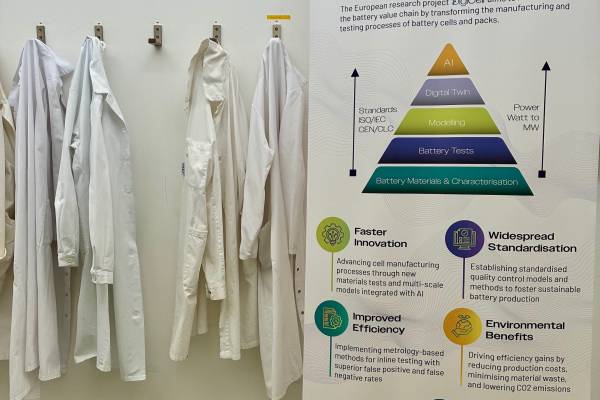

Over two days, partners highlighted their progress in understanding battery materials, improving data sharing, and linking experiments with digital models. A key focus was how detailed measurements at the material level can help predict battery performance and lifetime more reliably, supporting safer and more efficient energy storage. The consortium also discussed how artificial intelligence and digital twins of batteries are being developed to better understand aging, performance, and reuse. These tools help reduce trial-and-error in manufacturing and speed up innovation. Important steps were taken to ensure that project results are shared responsibly and can be reused beyond the project. This includes open data practices and contributions to international standards.

Key highlights include:

- Progress in new battery materials and testing methods

- Strong links between experiments, digital models, and pilot production lines

- Plans for workshops, videos, and a final public conference in 2026

With its final year underway, DigiCell is now focusing on turning research results into lasting impact for industry, policy, and society, contributing to Europe’s transition toward sustainable and reliable energy technologies.

A big thank you to our hosts in Linz! You made us feel very welcome.